Home

Mig Welding Process Advantages And Disadvantages . Carefully observing the work after finishing it will help you realize the finish quality. Vertical up position welding with mig is most difficult 2.

Gas Metal Arc Welding Gmaw from image.slidesharecdn.com Another popular welding method is gas metal arc welds, or mig welding. For most applications you will need the. It employs a consumable wire that acts as both the electrode and the filler material. Gas tungsten arc welding, gtaw, is slower than other welding techniques, as quality comes at the expense of time typically. Mig welding must be taken proper maintenance to protect the welder as it is an open arc method like other welding methods.

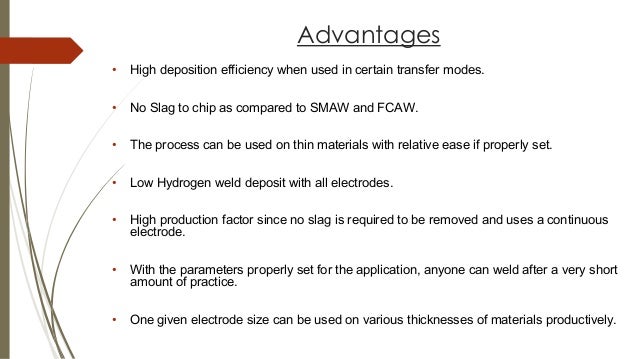

Examine the following list of pros to see if it's the right welding process for your requirements: Mig stands for metal inert gas welding or sometimes it is known as gas metal arc welding. High quality and clean weld. It needs no external shielding gas, which saves money. Gas tungsten arc welding, gtaw, is slower than other welding techniques, as quality comes at the expense of time typically. The gmaw or mig welding process are mostly used in automotive industries and pipe industries, building bridges and in the repair work. Before discussing the advantages and disadvantages of mig welding, it's essential to first have a clear idea of which mig welder to use and what it will be used to accomplish.

Source: slideplayer.com It needs no external shielding gas, which saves money. The equipment required is not very expensive. Gas tungsten arc welding, gtaw, is slower than other welding techniques, as quality comes at the expense of time typically.

And b) its inapplicability in certain cases. Despites the great benefits of mig welding, the following are disadvantages of this welding process. The reason this is a disadvantage is that depending on the situation as it can be pushed away from the weld if you would happen to have to much wind.

Mig welding must be taken proper maintenance to protect the welder as it is an open arc method like other welding methods. Advantages and disadvantages of pulling in mig welding. But what are the headline advantages and disadvantages of mig welding.

Source: image.slidesharecdn.com This is because the process produces a lot of spatter, heat and sparks. As with tig welders, these will not give any problem when doing an assembly job in any position. Disadvantage the next disadvantage with mig welding is that it needs a shielding gas to protect the weld.

Tig process produces high quality and high purity weld compare with other types of weldings because it offers great control over the weld area. All those have potential to cause such problems as incomplete fusion, porosity, poor bead appearance, and even cracking. It takes a good amount of time to prepare the metal from the welding work with this welding machine.

Carefully observing the work after finishing it will help you realize the finish quality. Examine the following list of pros to see if it's the right welding process for your requirements: This type of welding machine has more advantages than disadvantages.

Source: weldersmen.com Your welding device can be used better if you are familiar with the mig welding advantages and disadvantages. Advantages and disadvantages of pulling in mig welding. And b) its inapplicability in certain cases.

This method takes more time to prepare and the welding process takes longer. High quality and clean weld. Mig welding advantages and disadvantages.

Mig welding advantages and disadvantages. (1) the major disadvantage of mig welding is that it cannot be used reliably in the vertical or overhead welding positions due to the high heat input and the fluidity of the weld puddle. You can control the level of heat input as well as the speed of the filler rod.

Source: www.golden-elephant.com Stick welding is effective even when it's windy or raining. Disadvantages of gmaw (mig welding) gmaw process is sensitive to contaminants, it can only handle low to moderate levels of surface contaminants such as the rust, mill scale, the dirt, the oil and the paint, all these have potential to create the problems such as the porosity, the incomplete fusion, the bad bead appearance and even cracking. This type of welding machine has more advantages than disadvantages.

Mig welding advantages and disadvantages. Disadvantages 1) higher initial setup cost 2) atmosphere surrounding the welding process has to be stable (hence the shielding gasses), therefore this process is limited to draught free conditions 3) higher maintenance costs due to extra electronic components The advantages of gmaw welding are very efficient processes, do not cause scale, fast processing, can be used in all welding positions.

The reason this is a disadvantage is that depending on the situation as it can be pushed away from the weld if you would happen to have to much wind. Lastly, you'll understand all the advantages and disadvantages of mig welder. High quality and clean weld.

Source: weldersmen.com Mig welding is a popular method used in order to fuse different metals together. All those have potential to cause such problems as incomplete fusion, porosity, poor bead appearance, and even cracking. Your welding device can be used better if you are familiar with the mig welding advantages and disadvantages.

Today we will learn about what is mig welding principle, working, equipment's, applications, advantages and disadvantages. If you have any query then. What are the advantages of the mig welding:

Gas tungsten arc welding, gtaw, is slower than other welding techniques, as quality comes at the expense of time typically. Disadvantages of welded connections (1) welding requires skilled labour and supervision. (ii) testing a welded joint is difficult.

Source: slideplayer.com And b) its inapplicability in certain cases. It employs a consumable wire that acts as both the electrode and the filler material. You can control the level of heat input as well as the speed of the filler rod.

Disadvantages 1) higher initial setup cost 2) atmosphere surrounding the welding process has to be stable (hence the shielding gasses), therefore this process is limited to draught free conditions 3) higher maintenance costs due to extra electronic components So, without any further ado, let's gouge deeper on what is the difference between mig and tig welding. The professionals are certainly further vital than a number of detrimental features of mig welding device.

Before discussing the advantages and disadvantages of mig welding, it's essential to first have a clear idea of which mig welder to use and what it will be used to accomplish. But what are the headline advantages and disadvantages of mig welding. Stick welding is effective even when it's windy or raining.

Thank you for reading about Mig Welding Process Advantages And Disadvantages , I hope this article is useful. For more useful information visit https://labaulecouverture.com/